Circular Economy Initiative Deutschland

© Mohit Kumar on Unsplash

Background and aims

The Circular Economy Initiative Deutschland (CEID) has set itself the challenge of creating a Roadmap for a sustainable circular economy in Germany. Within the initiative, actors from science, industry and civil society work together to accomplish this goal by identifying new ways of building a circular economy.

Most current patterns of production and consumption follow a linear “extract, produce, consume, dispose” model. This form of economy is associated with high costs for humans and the environment – climate change and environmental pollution are among the consequences. The concept of the Circular Economy aims at a fundamentally change by optimising material and energy cycles and – as far as possible and ecologically sensible – closing them. Which change processes along the entire value chain are necessary are discussed by economic, scientific and societal stakeholders within the Circular Economy.

Structure

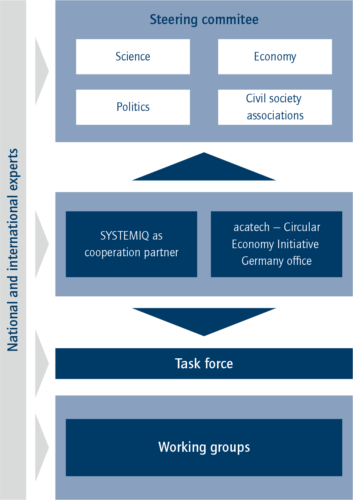

The CEID brings together stakeholders from industry, academia and civil society organisations. It aims to develop a joint target vision for Germany, to investigate concrete applications, to support their implementation and to identify beneficial framework conditions. This takes place in various committees. The working groups form the core of the initiative, where the interdisciplinary and cross-stakeholder dialogue between the experts involved takes place. The Steering Committee forms the management and strategy level of the initiative. The Task Force consists of representatives of the companies, scientific institutions and civil society organisations represented in the Steering Committee, as well as the CEID office and the cooperation partner SYSTEMIQ.

The CEID is funded by the Federal Ministry of Education and Research. The initiative is executed under the guidance of acatech – National Academy of Science and Engineering in cooperation with SYSTEMIQ. The acatech Vice-Presidents Thomas Weber hold the chair of the initiative.

Working Groups

In interdisciplinary and cross-sectoral working groups, some 130 experts from science, industry and civil society discussed how circular economic systems can be enabled and implemented. To this end, they examined possible fields of application and discussed which framework conditions could lead to successful implementation. The findings provided the basis for the transformation pathway set out in the Circular Economy Roadmap for Germany.

WG Circular Business Models

In the working group, the members focus on existing and possible circular business models and analyse the necessary framework conditions for their implementation. In a first step, the work of the experts addresses the development of a business model typology based on which the necessary technological preconditions are identified. A particular focus is on the role of digital technologies. Based on this, the economic viability of the respective business models will be examined and the necessary regulatory framework conditions for their successful implementation will be investigated.

Working Group Leads

- Patrick Wiedemann

Reverse Logistics GmbH - Prof. Dr. Erik Hansen

Johannes Kepler University Linz (JKU)

WG Traction Batteries

The working group discusses challenges and opportunities in the resource-efficient, circular management of traction batteries for electromobility in individual transport. The starting point is the formulation of a target vision for the year 2030 along the qualitative dimensions of regulation, material flows, technical developments, value creation networks and implementation within companies. In order to achieve this target, recommendations for action are proposed to politics, industry and science and summarised in a consecutive order in a roadmap. These results are supplemented by the development of excursuses and pilot profiles that analyse up topics of central importance for the transformation process in more depth and outline concrete implementation steps.

Working Group Leads

- Dr.-Ing. Christian Hagelüken

Umicore AG & Co. KG - Prof. Dr. Arno Kwade

Technical University of Braunschweig

WG Packaging

In the working group, the members address concrete challenges of Circular Economy approaches in the packaging industry along the entire value chain. The results of the working group include, on the one hand, a target vision for a circular packaging industry that discusses various circularity levers and derives the need for action for all relevant stakeholders in order to achieve the goal of a climate-neutral Circular Economy by 2050. On the other hand, the status quo and barriers to the circularity of (plastic) packaging are examined in depth using two case studies, HDPE bottles for liquid detergents and PET trays for food. Building on this, the experts in the working group have identified six starting points for transforming the packaging industry into a system based on circular value creation.

Working Group Leads

- Prof. Dr. Thomas Müller-Kirschbaum

Henkel AG & Co. KGaA - Prof. Dr Peter Elsner (until May 2022)

Fraunhofer Institute for Chemical Technology (ICT)/Karlsruhe Institute of Technology (KIT) – Peter Elsner passed away in May 2022

Publications

Circular Economy Roadmap for Germany

We are going through a period of comprehensive dynamics: a time characterised by the rapid development of new technologies, new patterns in consumer behaviour, the linking of previously separate value chains to form new solutions, an enthusiasm for new business models fuelled by the capital markets, and last but not least a state that is framing and investing more strongly.

At the same time, the current prevalent production and consumption logic of “take, make, waste” – also referred to in German as the “throwaway society” – is increasingly reaching its planetary limits. The economic transformation is particularly urgent at the moment against the backdrop of exponentially worsening, multiple crises. Specifically, the exatraction and processing of natural resources causes 50 per cent of global greenhouse gas emissions and 90 per cent of biodiversity loss and water stress.

In this context, the Circular Economy offers Germany an overarching narrative that can unite economic and environmental policy in response to this new dynamic and thus contribute significantly to achieving the goals of the European Green Deal (especially climate neutrality 2050). Because the Circular Economy can address the related systemic crises of climate, resource use, biodiversity and global health at the same time if it is implemented consistently and in good time in the sense of a holistic systemic solution. Thus, the successful implementation of a Circular Economy is not an end in itself, but combines climate and resource protection with cultural change, increased competitiveness and independence from raw materials, as well as the creation of employment and local value creation in the sense of sustainable win-win solutions.

Based on the overarching narrative of uniting ecological, economic and social perspectives, the Circular Economy Initiative Deutschland (CEID) has defined a target vision:

“A systemically thought and sustainable Circular Economy comprehensively contributes to the EU target of net zero greenhouse gas emissions by 2050 and enables an absolute decoupling of economic growth from resource consumption. It ensures compliance with planetary boundaries and sustainability goals and contributes to enhancing quality of life and securing equitable prosperity through collaborative, cross-business value creation and innovation.”

The CEID, as a multi-stakeholder initiative involving over fifty institutions from science, industry and civil society, has created the foundation for this target vision. In interdisciplinary and cross-sectoral working groups, around 130 experts discussed how circular economic systems can be enabled and implemented. To this end, they examined possible fields of application and discussed which framework conditions could lead to successful implementation. The Circular Economy Initiative Germany defined goals for this change process and focused on the following topics:

- Circular business models and digital technologies as drivers for innovation

- New value networks for batteries and packaging

- Framework conditions for a circular transformation and assessment of the ecologic and economic potentials of a Circular Economy

The “Circular Economy Roadmap for Germany” synthesises the findings from the various CEID working groups and summarises them in a consolidated statement with a claim to shape society as a whole. Developed and supported by a large number of social actors from science, industry and civil society, the focus of this roadmap has thus been, from the very beginning, on shaping a consistent, common target vision for a Circular Economy in 2030 and formulating concrete recommendations for action.

The “Circular Economy Roadmap for Germany” is a scientifically based framework for action that systemically describes the necessary steps for Germany’s transition to a Circular Economy. It contains recommendations for action that are intended to provide orientation for decision-makers from politics, industry and science.

Circular Business Models: Overcoming barriers, unleashing potentials

Business models are key to promoting acceptance of the circular economy among companies. Ideally, a business model should align circular value creation activities with opportunities to capture economic value. However, a circular economy cannot be achieved through the isolated optimisation and profit maximisation of individual actors’ business models. Effectively transforming existing value chains into value cycles requires a holistic approach and the design of circular ecosystems consisting of complementary value-generating actors.

The report describes 22 main business model patterns that provide decision-makers from business with guidance for determining the best system configurations. The patterns are based on a) role in the value cycle, b) core circular strategy and c) related service level. In addition to analysing (regulatory, financial, technical, etc.) barrier categories, a number of often mutually reinforcing barriers to core CE strategies were identified between a) providers (suppliers, producers, retailers, repair providers, logistics providers, etc.), b) users (both professional users such as businesses and consumers) and c) the product (i.e. technology, design) and related services.

Digital technologies have huge potential for connecting smart CE strategies by facilitating everything from retrospective data analysis to AI-enabled data forecasting. Through targeted provision of the relevant information, digital technologies can play a key role in overcoming barriers to circular business models and enabling the operationalisation of circular material, component and product flows.

At present, we lack a consistent regulatory framework for a circular economy. Instead, aspects relating to the CE are addressed by different, sometimes conflicting regulations such as waste legislation and the EU Ecodesign Directive. It is therefore important to develop a holistic regulatory framework that prioritises waste prevention through the extension of product lifetimes, reuse, remanufacturing and the formulation of circular product design requirements and standards.

Resource-Efficient Battery Life Cycles – Driving Electric Mobility with the Circular Economy

The strong growth currently occurring in the global traction battery market is projected to continue in years to come. This trend has huge potential, not only for decarbonising road transport but also for creating new economic value and increasing prosperity. However, it will be vital to minimise the associated environmental and social challenges (e.g. environmental pollution, occupational safety issues and human rights violations) across the entire supply chain, from raw material extraction to recycling.

Circular economy measures have significant potential for reducing material demand and greenhouse gas emissions. Computer modelling shows that, by 2030, 8,100 tonnes of lithium, 27,800 tonnes of cobalt and 25,700 tonnes of nickel could be recovered from vehicles in the German market. Moreover, recycling traction batteries in Germany would deliver cumulative energy savings of 308 petajoules by 2050. This is equivalent to the primary energy consumption of the city of Hamburg in 2019.

The transition to a sustainable, circular battery economy will require measures to be implemented across the entire value chain. To this end, the working group is developing a roadmap and common vision outlining how to achieve a step-by-step transformation between now and 2030. In addition, the three pilot profiles “Understanding of Battery Life”, “Model-Based Decision-Making Platform” and “Dismantling Network for Traction Batteries” set out further implementation steps for topics that will be key to the success of a circular economy. Finally, five special focus pieces discuss and make recommendations on a range of issues including battery second life, battery recycling and the role of deposit schemes.

Regulatory measures and incentives initiated by the German government, the institutions of the European Union and transnational corporate partnerships are essential for creating an effective market environment for the traction battery circular economy. These include the creation of a level playing field for the economic actors by harmonising the relevant legislation, clear definitions, common standards and (IT) infrastructure, and incentives for the return and high-quality reuse or recycling of traction batteries. These measures should address various points of intervention in the circular economy, including incentives to promote product and system design for circularity, embedding traction batteries in resource-producing ecosystems during use, ensuring a high collection rate at end of life, and establishing appropriate definitions and high, binding recovery rates.

Plastics Packaging in a Closed Loop – Potentials, Conditions, Challenges

Packaging performs important functions that add economic, environmental and social value, making it indispensable to our modern lifestyle. However, as the amount of packaging we use increases, so does the amount of waste it generates. Plastic packaging in particular has become a highly charged social, political and environmental issue, as growing quantities find their way into the environment. Germany’s effective collection, sorting and recycling structures prevent packaging waste from entering the environment directly. However, even Germany, with its reputation for efficient recycling, has a comparatively low mechanical recycling rate for plastic packaging of 47%, while recycled materials account for just 10.9% of the plastics used in the packaging industry.

The public and policy debate about plastic packaging has already led to many positive changes in industry, but has also resulted in opportunities for political gain and knee-jerk reactions that are not always in the best interests of the environment. Consequently, the working group set out to provide an objective, well-founded basis for the debate, so that truly effective measures can be prioritised, paving the way for a circular economy for plastic packaging in Germany that is compatible with other sustainability goals such as climate action.

In the course of its work, the working group has discussed the potential, barriers and possible trade-offs involved in a circular economy for plastic packaging, drafted a vision, undertaken two in-depth case studies of detergent packaging and cheese packaging, and formulated recommendations for the key stakeholders.

It also modelled the potential for reducing greenhouse gas emissions in circularity scenarios for 2030 and 2050. The results show that increasing the proportion of mechanically recycled material to 40%, the proportion of chemically recycled material to 20%, and the proportion of reusable packaging to 20% could save an average of approximately 4 million tonnes CO2e by 2050 compared to business [JB1] as usual. However, the modelling also shows that, in the absence of additional measures, there would still be a substantial shortfall in terms of achieving both climate neutrality and closed-loop recycling, even in 2050. To accomplish a rapid and effective transformation of the packaging industry to a system based on circular value creation, it will be necessary to establish a framework that enables holistic, common solutions. A haphazard collection of individual goals and flagship projects will not be enough – coordinated measures must be implemented across the entire value chain.

All publications are available on the Circular Economy Initiative website.

Further information