acatech HORIZONS: Urban Mining

The earth’s resources are finite. If we use them wastefully, they will not be able to sustain humanity in the long term. Nevertheless, anything that has reached the end of its useful life is very often thrown away after a short time. This is precisely where urban mining comes in: instead of mining more and more primary materials, the aim is to consistently reuse the stocks of secondary materials which have previously lain unused in cities and settlements. These materials range from building materials to the precious metals in electronic parts to plastics, which until now have often been thrown away. This is partly due to a lack of the data required to locate, reprocess and recycle them. But what are the barriers and how can they be

overcome? What is the current state of play and just what will be possible in the future? This issue of HORIZONS focuses on these and other fascinating questions.

HORIZONS is also on LinkedIn. Follow us for “science in snacks”.

The acatech HORIZONS Podcast

“Late Night Tech” is a podcast for everyone who is up for science, technology and community insiders. Christina Müller-Markus and Dr. Sandra Fendl from the acatech HORIZONS team talk with well-known experts about current topics. A podcast from acatech, the National Academy of Science and Engineering.

What is Urban Mining?

Urban mining concerns each and every one of us. Everything that humans have ever made and used is part of a huge storehouse of raw materials: entire cities, settlements, conurbations or production sites. We are thus facing a paradigm shift. Bridges, old buildings, factories, worn-out (durable) consumer goods – basically anything that humans have produced and later discarded or regarded as useless is no longer waste but valuable (buried) treasure lying dormant on our doorstep, waiting to be dug back up. Urban mining is about systematically finding this buried treasure and reprocessing it to a high quality so it can be put to renewed use. Implementation is still in its infancy for many raw material groups: overall, only some 16 percent of raw materials used in the German economy are secondary raw materials.

What is already possible today and what will be possible in the future?

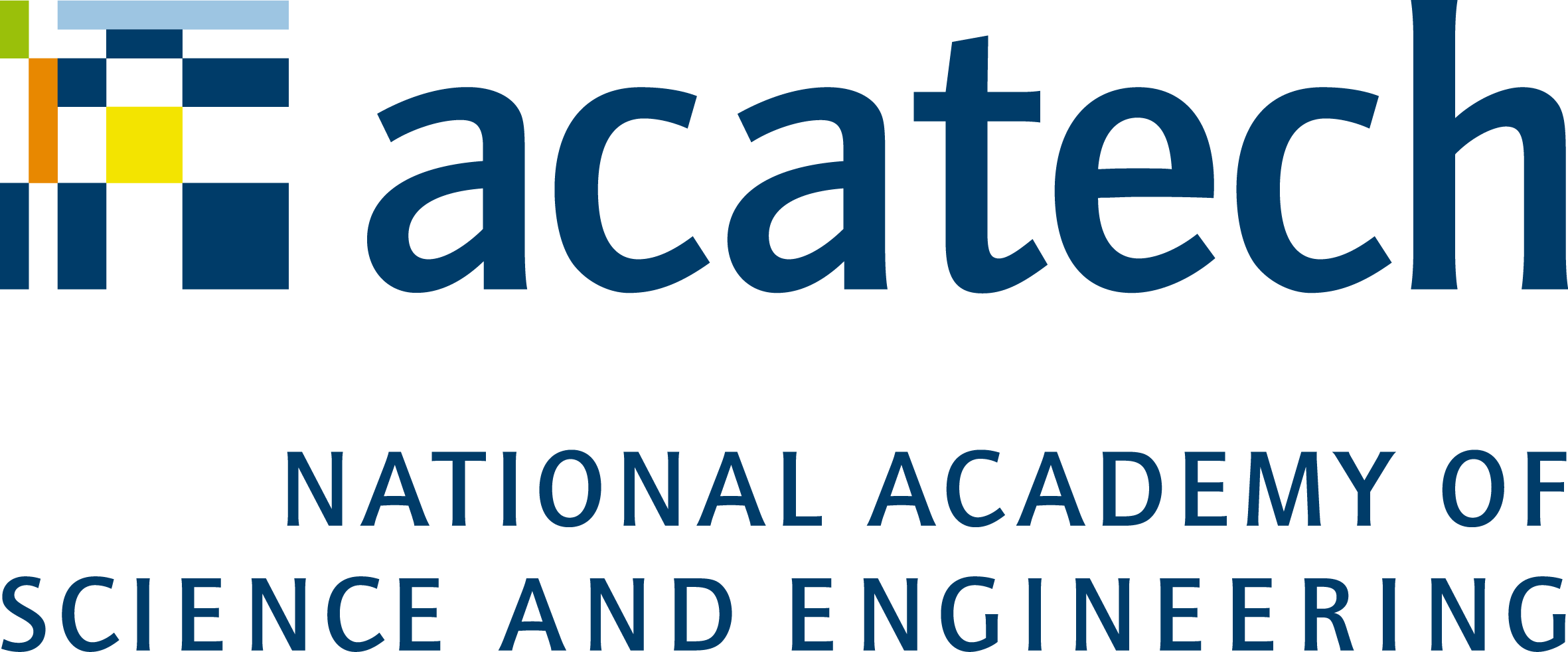

Valuable raw materials are found in smartphones, residential buildings, batteries, cars, textile products and much more. However, recovering these raw materials is not always easy. While many materials can already be recycled today, many new possibilities for recycling will emerge in the future. Science is already researching new, promising technologies in the laboratory. New business models will also emerge that can ensure greater sustainability.

What's inside a smartphone

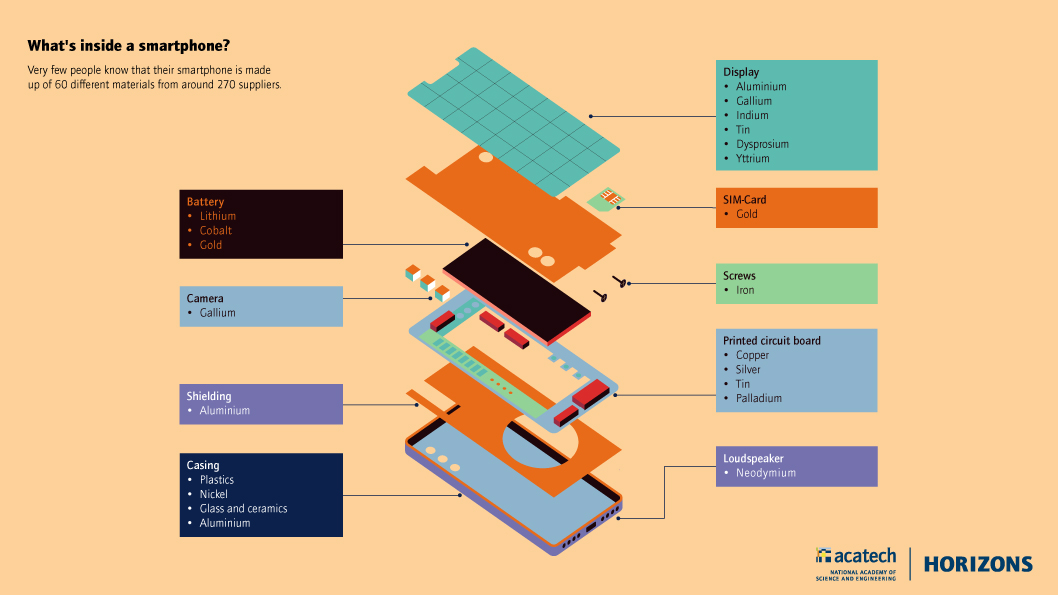

Recycled concrete: new life from waste

Over half of Germany’s waste is construction and demolition waste. The majority of used concrete ends up in road building. New scientific findings could mean that concrete can be recycled. There are even pilot projects to investigate how to build entire houses from recycled materials. But what is possible now and in the future?

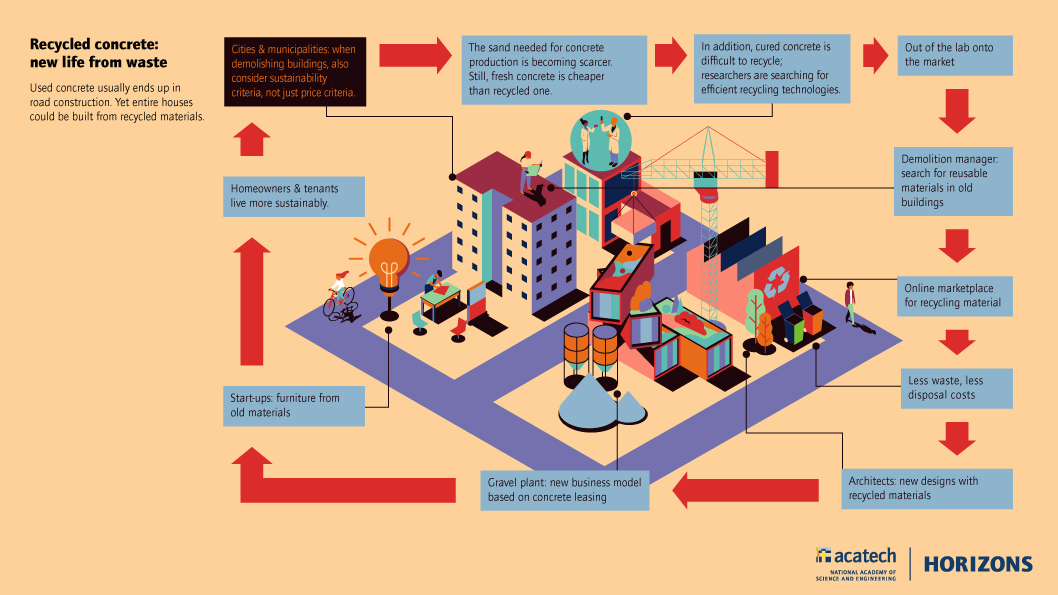

Bio-recycling: Bacteria breaking down plastics

Around 360 million tonnes of plastics are produced worldwide every year, about half of which ends up in landfills or in the environment. Polyethylene terephthalate, or PET for short, is one of the most important plastics. Every year, around 70 million tonnes of PET are produced worldwide – for short-lived goods such as bottles, food containers or packaging, and also for long-lived goods such as textile fibres for sportswear, carpets, laboratory containers or medical prostheses. In conventional mechanical recycling, the plastic is washed, shredded and melted. However, this cannot be continued indefinitely as this particular method used on a long term basis greatly reduces the quality of the plastic. A a new biotechnological recycling process might solve this problem.

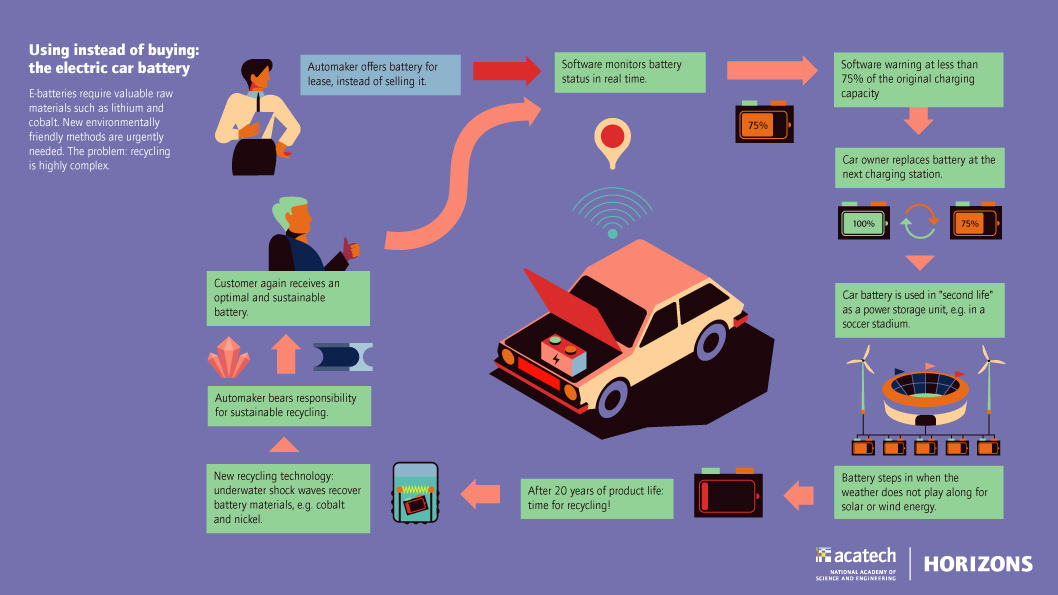

Use instead of buy: the electric car battery

An e-battery weighs around 700 kilograms and is extremely expensive. E-battery manufacture uses 40 per cent of the cobalt mined worldwide, the price of which has quadrupled in two years. Lithium is also needed for the battery and mostly comes from Bolivia and Chile. Once they have reached the end of their useful life, the lead-acid batteries previously used in conventional cars have often ended up in Africa, where they are reprocessed under questionable conditions and returned to Europe as “recycled” batteries. Recycling which respects the environment and human dignity is necessary, but difficult. E-batteries are so complex that they are very difficult to break down into their individual components. This is why an innovative approach is needed.

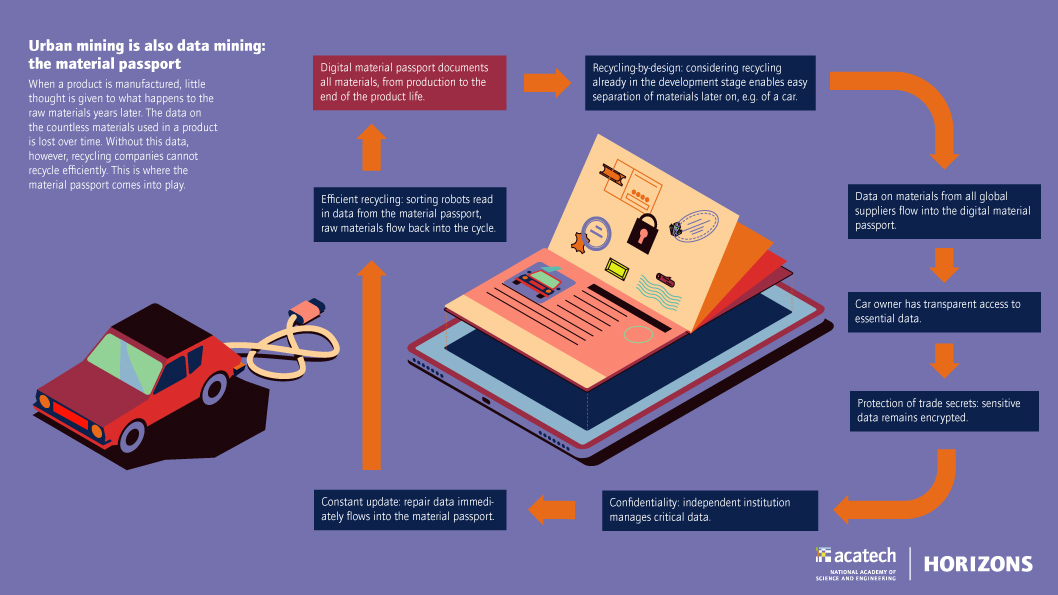

Urban mining is also data mining: the material passport

A car contains several thousand individual parts from suppliers in different countries. From the electronics to the body to the engine – there are many valuable raw materials everywhere. So far, little thought has been given to what will happen to these raw materials in ten or twenty years’ time. Car manufacturers are reluctant to share their material data. As a result, recycling companies lack raw material data. A much-appreciated solution: the material passport. The diagram explains how it works.

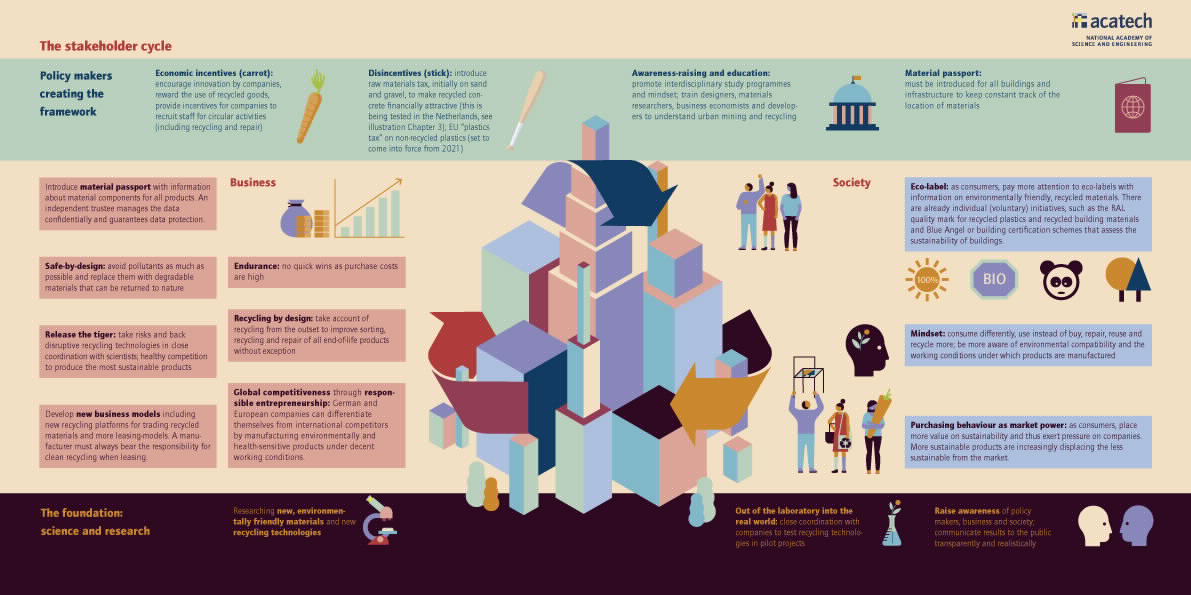

From rhetoric to implementation: the cycle of actors

The success of urban mining depends above all on the people who drive the issue forward. Because the best study and the latest recycling technology are of no use if they end up gathering dust in some research institution. The most innovative start-up idea for a sustainable business model will fizzle out if no investor believes in it. The most environmentally friendly product will not make it to market if the political framework is lacking. Urban mining can only work if all those involved think and act together and move towards their goal of achieving a balance between people, technology and nature.

The following illustration summarises what policy makers, business, academia and consumers can do in concrete terms. In a similar way to a loop or cycle in which raw materials are continually reused, there is also a stakeholder cycle.

Project group

- Prof. Dr. Manfred Hennecke (head of project group)

President (ret.), Federal Institute for Materials Research and Testing - Dr. rer. nat. Katrin Bokelmann

Fraunhofer Research Institution for Materials Recycling and Resource Strategies IWKS - Prof. Dr. Magnus Fröhling

Chair of Circular Economy, Technical University of Munich - Dr.-Ing. Andrea Gassmann

Fraunhofer Research Institution for Materials Recycling and Resource Strategies IWKS - Prof. Dr. Erik G. Hansen

Head of Endowed Institute for Integrated Quality Design (endowed by Quality Austria – Trainings, Zertifizierungs und Begutachtungs GmbH and the Province of

Upper Austria), Johannes Kepler University Linz - Prof. Dr. Hans-Joachim Kümpel

President (ret.), Federal Institute for Geosciences and Natural Resources, honorary member of Verband Bergbau, Geologie und Umwelt e.V - Dr. Christine Lemaitre

Managing Director, Deutsche Gesellschaft für Nachhaltiges Bauen e.V. (German Sustainable Building Council) - Dr. Guido Meurer

Member of the Board of Management, BRAIN AG - Stephanie Otto

Chairwoman of the Board of Management, Berliner Stadtreinigung - Dr. Bettina Rechenberg

Head of Division III, Sustainable Production and Products, Waste Management, German Environment Agency - Christian Schiller

Co-Founder and CEO, cirplus GmbH - Dr. Volker Thome

Head of department of Mineral Materials and Building Material Recycling, Fraunhofer Institute for Building Physics IBP

Overview: the acatech HORIZONS series

In the acatech HORIZONS series, the academy explores important technology fields that are already looming large on the horizon, but where there is still some uncertainty about their potential impacts. More

In the acatech HORIZONS series, the academy explores important technology fields that are already looming large on the horizon, but where there is still some uncertainty about their potential impacts. More