acatech and DECHEMA present meta-analysis of chemical industry transformation

Berlin, 27 April 2023

The meta-analysis shows that defossilisation of the chemical industry is contingent on the use of hydrogen as an energy carrier and as a feedstock

The chemical industry uses fossil resources such as natural gas not only for energy but also as a raw material. To achieve defossilisation, the industry must not only replace fuels but also switch to an alternative raw material base. The analysis of the use of hydrogen in the chemical industry, conducted by acatech and DECHEMA and published today, compares a number of scenarios envisaged by various research institutions. It shows that the chemical industry can reduce its fossil resource use by turning to hydrogen and its derivatives both for energy and as a feedstock.

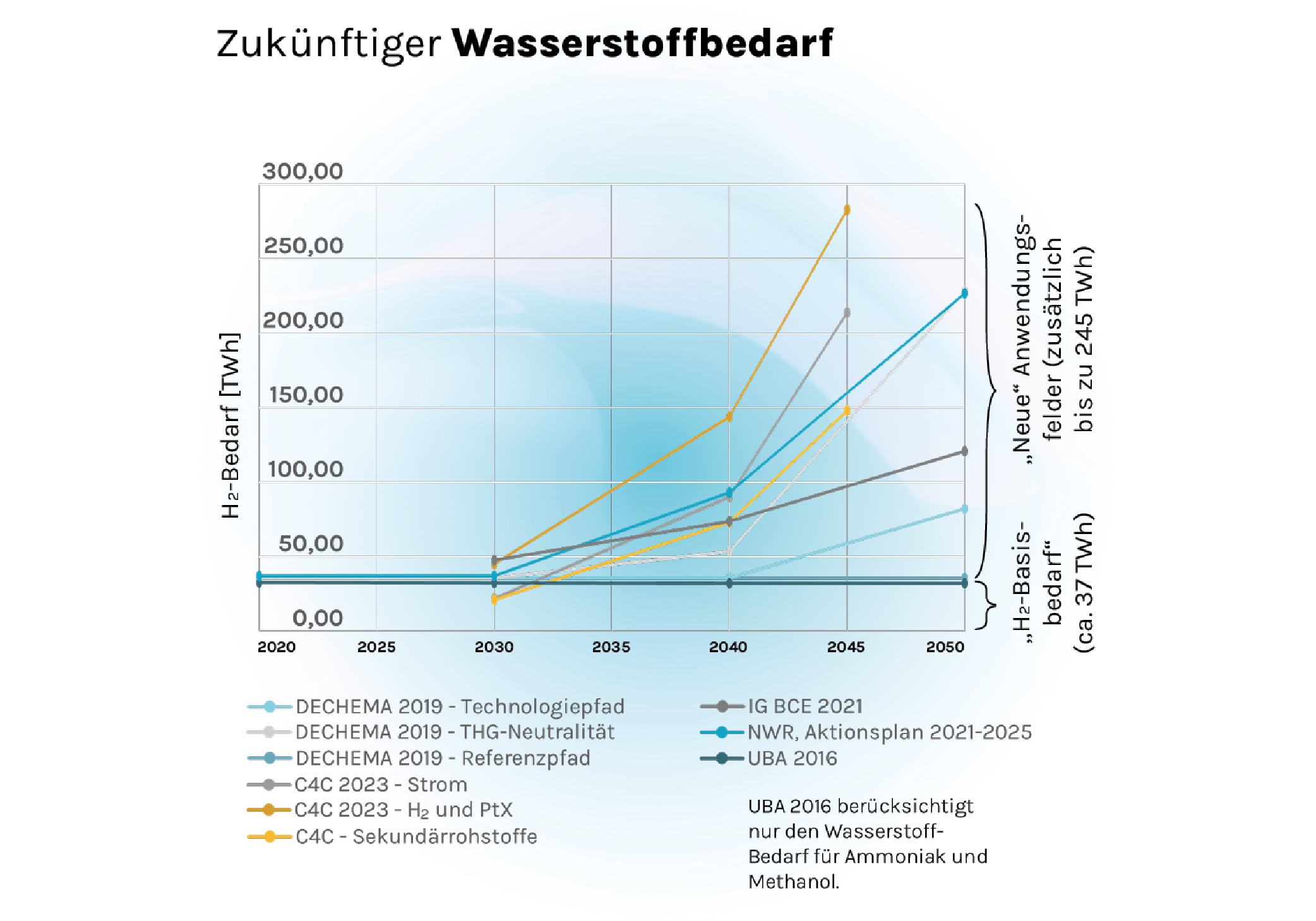

“The hydrogen demand of the chemical industry could at least double by 2050 with some scenarios suggesting a five- to sevenfold increase in demand,” said Jens Artz, project manager at DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V. “To be able to provide hydrogen in such quantities, the availability of sufficient amounts of cheap green electricity will be essential,” predicted Andrea Lübcke, project manager at acatech – National Academy of Science and Engineering. “The defossilisation of the chemical industry is also contingent on locations within the industry being connected to gas networks (hydrogen, CO2) and the electricity grid.”

Lipstick, carpets, detergents – consumer chemicals are numerous, diverse and an indispensable part of our daily lives. What they all have in common is that fossil resources such as naphtha and natural gas provide not only energy but also the raw materials for these products. For example, ethylene and propylene, major raw materials in plastic production, are obtained from naphtha.

Demand for hydrogen in the chemical industry

The chemical industry in Germany had a hydrogen demand of 37 terawatt hours in 2021, corresponding to around 1.1 million tonnes. Moving away from fossil resources may increase the demand for hydrogen in future. The scenarios examined in the meta-analysis indicate hydrogen requirements of between 80 and 283 terawatt hours in 2050. The large range results from the fact that the scenarios weight various hydrogen end uses differently. Nevertheless, most of the scenarios examined expect hydrogen use in the following areas:

- The current fossil-based hydrogen demand of 1.1 million tonnes must be met. For example, around 0.4 million tonnes of hydrogen, primarily produced from natural gas, is required for the manufacture of ammonia in Germany. This demand will remain in future and will require carbon-neutral hydrogen.

- To replace fossil resources used as a raw material, Fischer-Tropsch synthesis and the expansion of methanol-to-X processes are possible options. These are hydrogen-dependent processes. With Fischer-Tropsch synthesis, for example, synthetic naphtha is produced and can replace fossil-based naphtha, one of the most important raw materials in the chemical industry.

- The chemical industry requires high operating temperatures, ranging between 300 and 1000 degrees Celsius. In future, hydrogen or synthetic methane could be used to generate process heat. “Process heat from hydrogen (derivatives) will be relevant particularly when there is no electrifiable or biomass-based alternative,” said Jens Artz, DECHEMA.

- To close material loops, it is necessary to increase plastic waste recycling rates. If plastic waste is used again as a raw material, demands for virgin plastic production decline and this reduces the amount of fossil resources needed for plastic manufacturing. Today, approximately 65 per cent of plastic waste is burned for energy. To use plastic waste as a raw material and thereby replace fossil resources, it may be necessary to process it with hydrogen. The same goes for the processing of biogenic residues.

Switching to hydrogen and its derivatives will lead to higher energy requirements

In 2021, the chemical industry in Germany consumed around 450 terawatt hours of energy. This is more than 20 per cent of the energy consumed by all German industrial sectors combined. The meta-analysis makes it clear that, across all scenarios examined, models indicate an increase in final energy consumption due to the defossilisation of the chemical industry. It is therefore essential for the chemical industry to be able to access renewable electricity at affordable prices.

Switching to renewably produced hydrogen will cut greenhouse gases

Annually, the chemical industry produces up to 112 million tonnes of carbon dioxide equivalents. This accounts for all direct and indirect emissions produced when chemical products are manufactured, used or disposed of. “There is considerable potential to cut greenhouse gases here, which must be swiftly unlocked due to the Paris Climate Agreement,” said Andrea Lübcke. “If the chemical industry switches over to hydrogen produced from renewables, it can significantly reduce its greenhouse gas emissions.” Emissions can be reduced if hydrogen is produced without the use of fossil resources; for example, by the electrolysis of water using electricity generated from renewables. A second possibility is switching the raw material base with the aid of Fischer-Tropsch synthesis and methanol-to-X processes. Hydrogen is also required in these cases – ideally, hydrogen produced using renewable energy. In addition, hydrogen produced from renewables can be used to generate high temperatures. Also, the use of biomass and a better rate of plastic waste recycling will help to cut greenhouse gases and replace fossil raw materials.

Analysis of hydrogen use in the chemical industry is part of H2-Compass meta-analysis

The analysis of hydrogen use in the chemical industry published today is part of a meta-analysis conducted by acatech and DECHEMA as part of their joint H2-Compass project. The meta-analysis provides a general overview of a number of studies and scenarios on the future role of hydrogen in various end use sectors.

Further information:

Download of the analysis “Hydrogen in the chemical industry” (in German)